Understanding MPO and MTP® Cables

Key Differences and Benefits

The Basics

MPO (Multi-fiber Push On) and MTP® (Multi-fiber Termination Push-on) cables are foundational elements of modern fiber optic technology. Both are capable of bundling multiple fibers to support high-bandwidth transmissions required for today’s demanding applications. Despite their similarities, these two types of cables have distinct characteristics that make them unique.

MPO

Multi-Fiber Push On

MTP

Multi-Fiber Termination Push On

GigaTech MPO & MTP Cabling Solutions

- Corning ClearCurve Ultra-Bendable OFNP Plenum Wiring

- Low Insertion Loss, below industry standard for both connector types

- Under .01% fail rate, designed for lifespan of connections

- Lifetime Warranty

MPO & MTP® Connector: Mechanical Differences & Application

The differentiating factor between MPO and MTP® fiber optic cables resides in their connectors. With its advanced design, MTP® connectors offer superior mechanical characteristics and optical performance compared to MPO cables. These distinguishing features break down as follows:

MPO stands for ‘Multi-fiber Push On.’ MPO connectors are the generic model upon which MTP connectors are based. Here are the defining features and benefits of MPO cables:

MTP® is a brand name for the MPO connector developed and manufactured by US Conec Ltd. Here are the key differentiators and benefits of MTP cables:

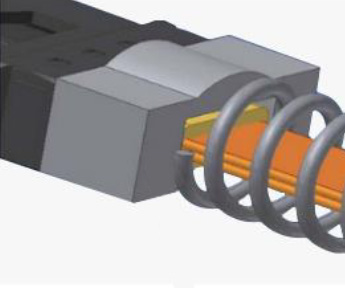

The Pin Clamp: Metal vs Plastic

- MTP® Connector: Metal pin clamp for stronger pin grip and reduced breakage risk

- MTP® Design: Oval spring protects fiber ribbon, ensures secure seating, and minimizes cable damage risk

The MPO connector typically features plastic pin clamps, which can easily break with frequent cable mating. In contrast, the MTP® connector utilizes a metal pin clamp, ensuring a robust grip on the pins and minimizing the risk of inadvertent breakage during connector mating. Additionally, the MTP® design incorporates an oval spring that maximizes the gap between the fiber ribbon and the spring, safeguarding the ribbon from potential damage during insertion and providing a secure spring seat with ample clearance, reducing the risk of cable damage.

MPO Plastic Pin Clamp

MTP® Metal Pin Clamp

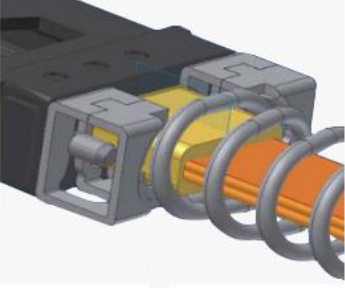

Floating Ferrule

- MTP® Connector: Includes floating ferrule for improved mechanical performance and consistent physical contact under loads

- MPO Connector: Lacks floating ferrule, making MTP® connector advantageous for Tx/Rx connections in parallel optics.

The MTP® cable incorporates a floating ferrule to enhance mechanical performance and maintain physical contact under applied loads. In contrast, the MPO connector does not have a floating ferrule, making the floating ferrule feature of the MTP® connector particularly beneficial for Tx/Rx device connections in emerging parallel optics applications.

The ferrule can move freely inside the MTP® housing while mated

Improved Guide Pin

- Multi-fiber connectors use coarse alignment adapters, unlike single fiber connectors.

- MTP® Connector: Employs stainless steel elliptical guide pin tips with tight tolerances for accurate alignment and reduced debris.

- MPO Connector: Uses chamfered shaped guide pins that can generate more debris during usage.

MPO Guide Pin

MTP® Guide Pin

Removable Housing for MTP® Connectors

- MTP® connectors: Removable housing facilitates rework, polishing, testing, and gender modification.

- MPO connectors: Lack removable housing, limiting rework and modifications.

- MTP® PRO cable: Enables field gender and polarity reconfiguration with integrity and performance.

Both MPO and MTP cables play significant roles in fiber optic networking. The choice between them often comes down to specific application needs, budget constraints, and future network scalability plans. Both cables are capable of supporting high-bandwidth transmissions and are suitable for various environments, including data centers and telecommunications. By understanding the key differences and benefits, you can make an informed decision that best suits your fiber optic requirements.

The MTP® Connector: Performance Upgrades

- MTP® connectors improve upon MPO connectors, addressing optical loss and packet drop concerns.

- MTP® connectors in MTP® cables feature precise alignment of male and female sides, reducing insert loss and return loss in high-density cabling systems.

- Insertion loss rates of MTP® connectors have greatly improved over time, now comparable to rates seen in single-fiber connectors.

- Latest MTP® cable formats offer enhanced plug-in capability, reducing accidental bumps and signal instability.

- Redesigned internal connector components ensure precise alignment, centered normal forces, and optimal lead-in shape.

- Improved stability, durability, and reliability of MTP® connectors, with reduced wear, tear, and debris during multiple plug-ins.