Fiber & Optic Cleaning Guide

Why, How, and When to Clean your Fiber Cables and Transceivers

Small dust = big problems.

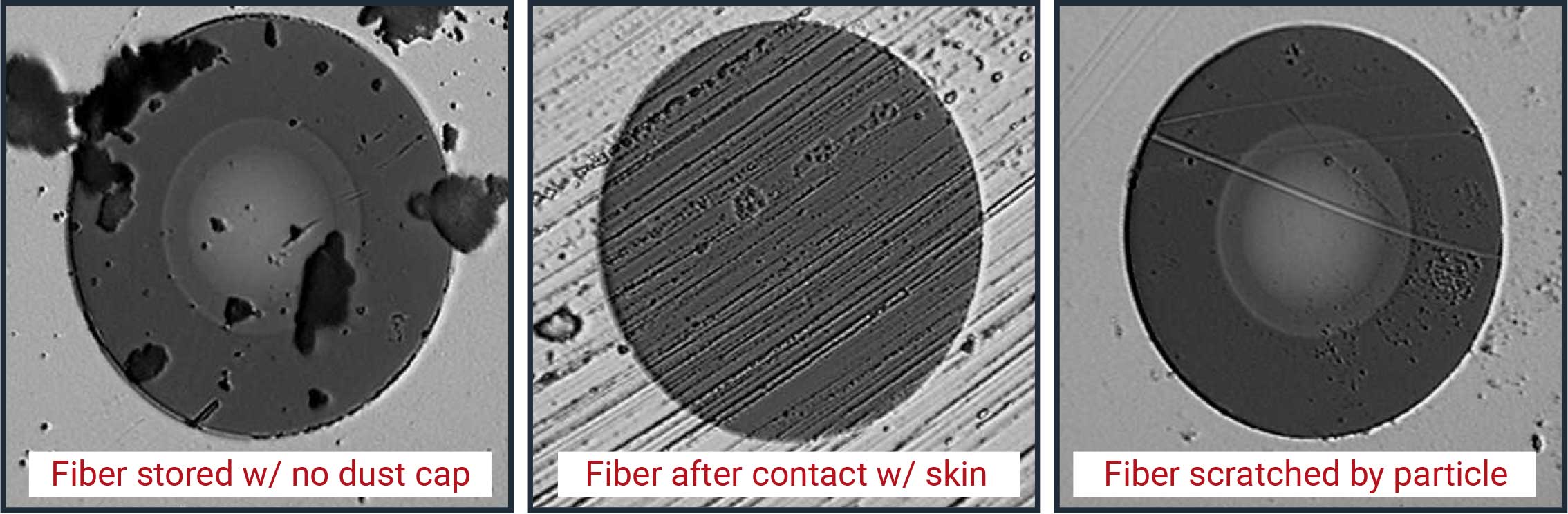

Contamination is the leading cause of optical failure in a network.

Optical Transceivers & Cabling require clean endfaces to fully transfer light. Obstructions can lead to multiple points of failure & possibly be damaged permanently.

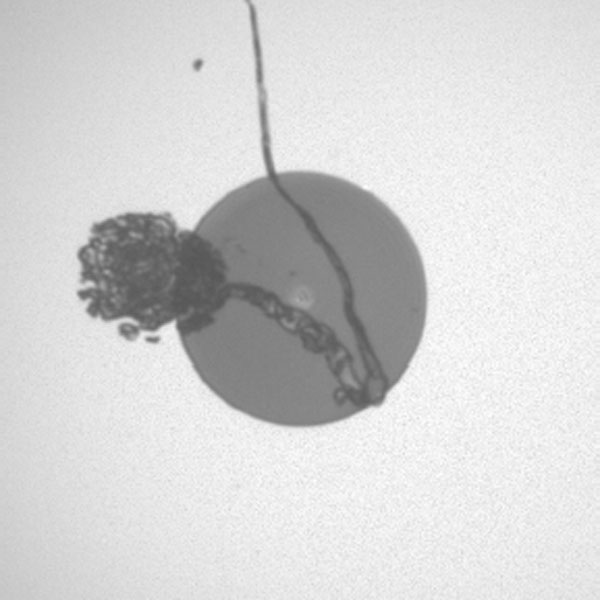

Contaminated Connector

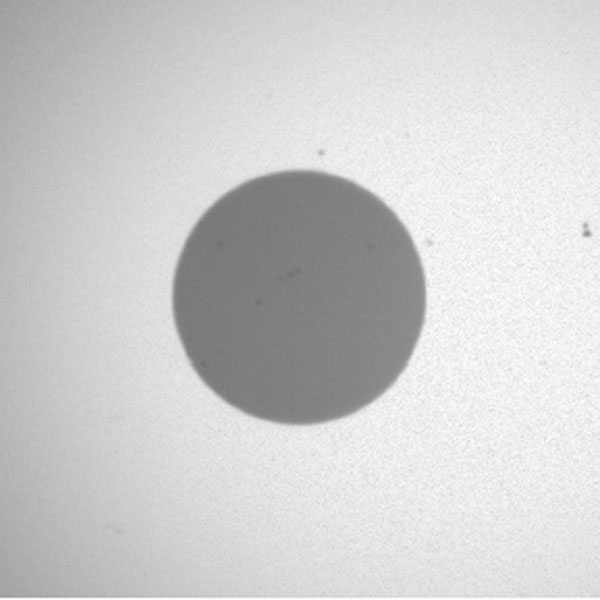

Clean Connector

To prevent cross-contamination, signal degradation, and network failure, you must clean both the Fiber Cable and the Transceiver before every installation; even microscopic debris on one surface can permanently scratch the other, compromising the entire link.

Common Errors Found by Contamination

-

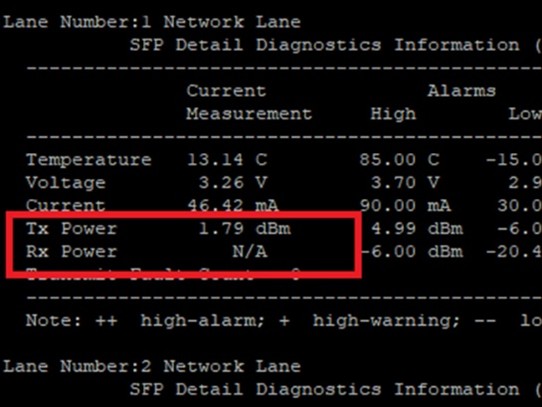

Low/Unstable Rx power

Contamination likely → ICI (Inspect/Clean/Inspect Again) both cable and transceiver. Reseat.

-

CRCs / Input Errors

Re-clean; If recurring, replace the patch cord.

-

Link Flapping

ICI (Inspect/Clean/Inspect Again) both cable and transceiver, reseat, verify latches fully engaged, check bend radius.

How To Clean a Transceiver

Use a Pen Fiber Cleaner inside the transceiver port.

• Insert the cleaner tip straight into the receptacle.

• Press to activate the cleaning pen.

• Repeat as needed (typically 2–3 clicks).

How To Clean a Fiber Cable

• Pen Fiber Cleaner

Use a Fiber Cleaning Cassette on the connector endface:

• Press the lever or shutter on the cassette to advance a fresh section of the cleaning ribbon.

• Hold the connector perpendicularly to the exposed cleaning surface.

• Gently press the connector endface against the tape and slide it in a straight line in the direction of the arrow indicated on the tool.

• Repeat as needed ensuring the cassette lever is reset to use a fresh section of the cleaning ribbon per application.

Alternative Method – Use a Pen Fiber Cleaner on the connector endface:

• Align the cleaner tip with the connector tip.

• Press to activate the cleaning pen.

• Repeat as needed (typically 2–3 clicks).

• Before handling any module, confirm that the device is powered down and handle all optics carefully to avoid damage.

• Only use approved fiber-optic cleaning tools, such as Pen Fiber Cleaners and Cleaning Cassettes.

• Do not use alcohol-based cleaning tools.

• Avoid touching the fiber endface at all times.

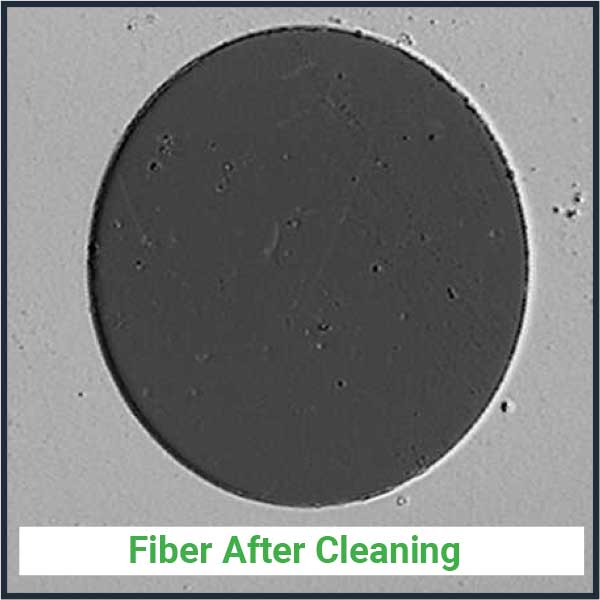

The 30-Second Method: ICI (Inspect/Clean/Inspect Again)

-

Inspect

BOTH endfaces with a scope.

-

Clean

BOTH the fiber connector + port (or transceiver) (1–3 clicks with the right tool).

-

Inspect Again

Connect only when clean.

Minimal Kit (what you actually need)

- LC/SC/MPO one-click cleaners

- Fiber Connector Cassette

- Handheld inspection scope

- Dust caps for every unplugged end

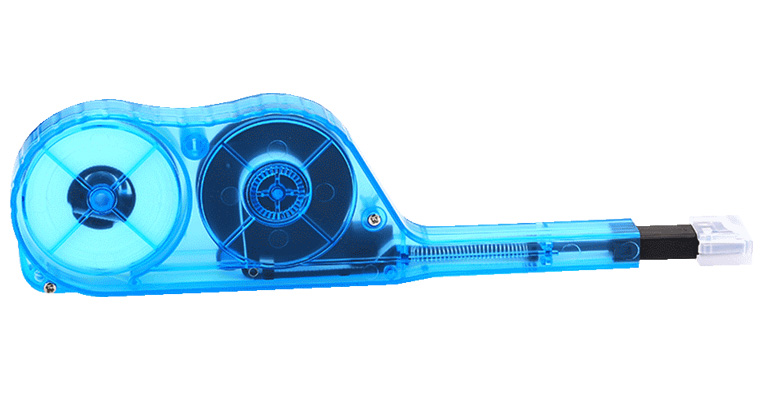

Reel-type cleaners quickly and effectively clean a variety of connectors. Reel-type cleaners are a safe cleaning option without the need for alcohol, which can be toxic and flammable. They have refillable cleaning tapes making them ideal for lab, assembly lines and field use.

Designed for cleaning LC and MU type connectors, this fiber cleaner can easily remove dirt, dust, oil and grease from an optical fiber adaptor. With the ability to each into the entire area within the connector, it makes cleaning of the ferrule endface a simple task with the push of a button.

This push-type cleaner is specifically designed for the cleaning of ferrule endfaces in MTP/MPO adapters. With the ability to clean all 8/12/24 fibers simultaneously it is a time and cost efficient tool for the maintenance of fiber cables. Can clean both exposed jumper ends as well as connectors embedded in the adapter.

Does & Don'ts

Do

- Cap every unplugged connector and module immediately

- Store cleaning tools sealed; replace dirty tips/wipes

Don't

- Don’t connect before a clean inspection result

- Don’t touch ferrules or look into active ports

When to Clean – ICI (Inspect → Clean → Inspect)

-

At Install

ICI every mating pair + ports

-

After any service touch

ICI before reconnect

-

If errors / loss appear

ICI both ends first, then escalate