Fiber Cable Maintenance

Cleaning Procedures for Fiber Cable Connections

The most prominent cause of fiber-optic dropped packets or network outages comes from dirty or comprised fiber connections. If a particle of dust, lint, oil, or any other dirt gets on the end of the connector, it will interrupt the signal being sent. These seemingly small particles can throw a hiccup in the data transfer capabilities of your network, leading to costly network failures and downtime. It is important to address why clean environments and proper cleaning maintenance of your fiber transceivers and cables is necessary for the health of your network.

Signs a fiber connection may be contaminated

Performance Monitoring

Signs of contamination usually exhibit themselves in the form of performance degradation

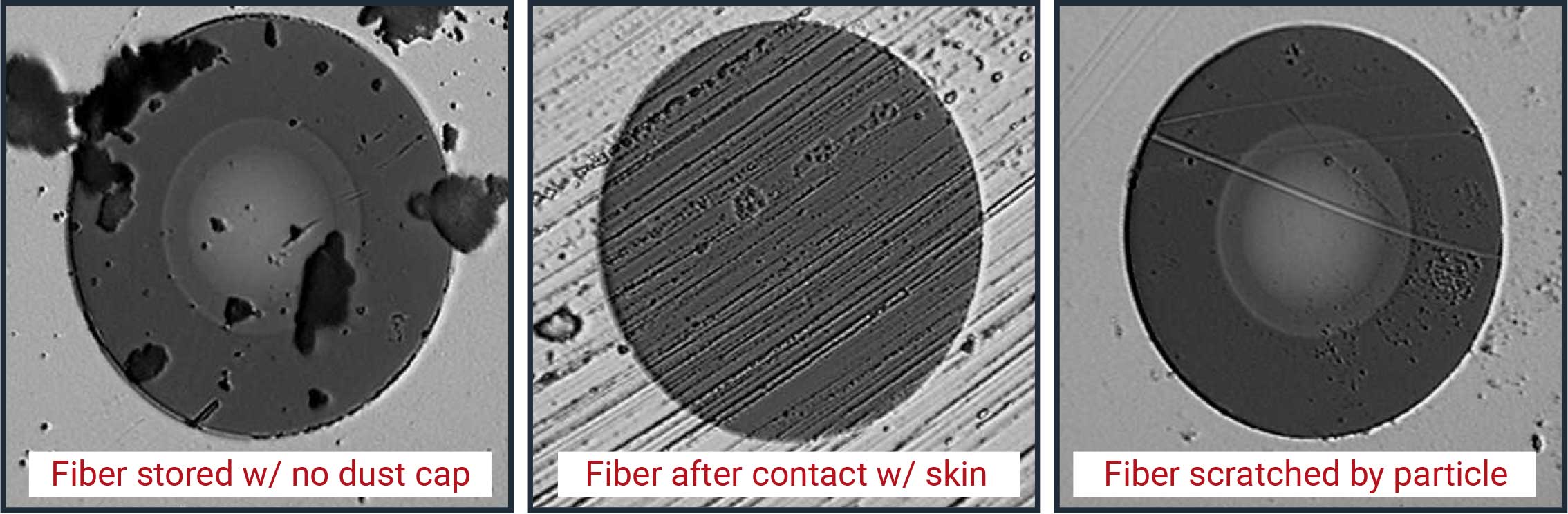

Scope Inspection of Contaminated

LC Fiber Connection

Guide Menu

Cable Inspection & Diagnosis

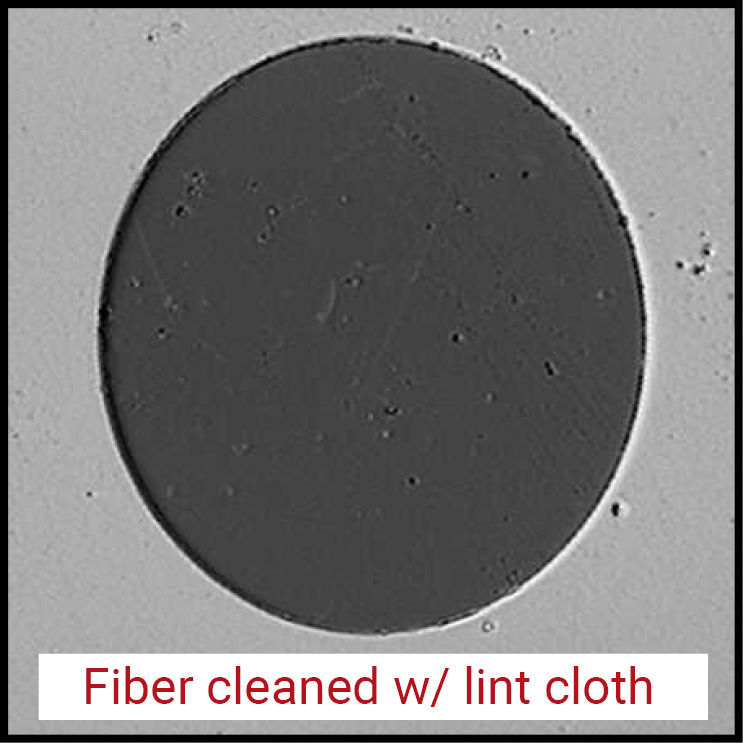

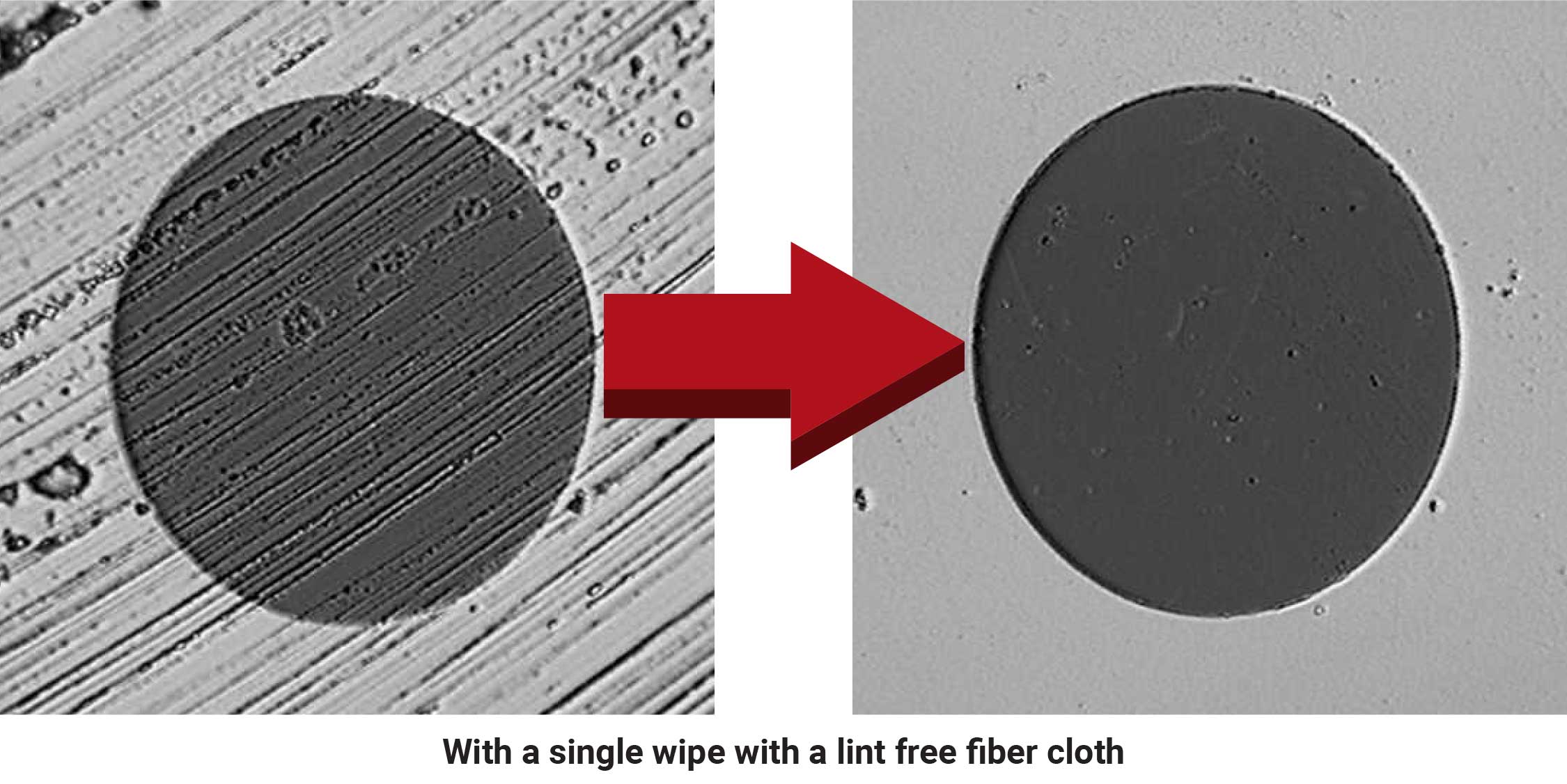

Examining a fiber core with an Integrated Fiber EndFace Inspector can help identify when damage or contaminates are effecting the throughput of light in the fiber.

Why is maintenance important?

In order to maintain optimal performance in a fiber network, it is paramount that fiber never be left exposed. Maintaining clean connections ensures your cables will perform to their proper specifications. Transceiver connectors and fiber cables should always be plugged in or covered with a dust cap in order to protect the fiber core. Any contamination in a fiber connection can cause failure of the component or the whole system overall. Microscopic dust particles that partially or completely block the fiber core generate strong back reflections which in turn cause instability in the laser system.

If a fiber cable was cleaned and properly inspected upon original installation, there are still ways in which the connectors can acquire contamination over time, even if the cable has never been removed. Here are some potential causes:

Airflow

Wear and Tear

Condensation

Enclosures

Airborne Contaminants

Microscopic Particles

Degradation of Materials

Diagnosing Connector Contamination

Visual Inspection

Physical Environment Monitoring

Optic Baseline Monitoring

How To Clean a Fiber Cable

• Non-abrasive cleaner (air duster)

• Before handling any module, confirm that it's powered down and treat each module delicately.

• Only use Clean Dry Air (CDA) or a trusted source of canned compressed air.

• While using compressed air, keep the can in a vertical position. Angling it might cause unwanted liquids to be discharged with the air.

General Guide For When to Clean

Cable Maintenance Products

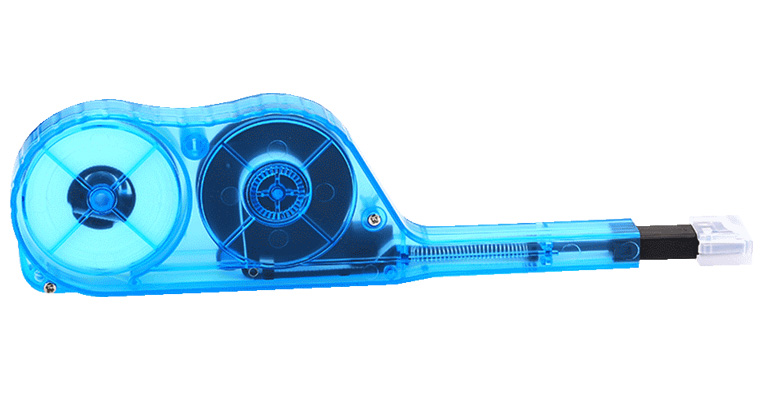

Reel-type cleaners quickly and effectively clean a variety of connectors. Reel-type cleaners are a safe cleaning option without the need for alcohol, which can be toxic and flammable. They have refillable cleaning tapes making them ideal for lab, assembly lines and field use.

For Fiber Connectors (LC, SC, ST, FC, MT, MU)

Designed for cleaning LC and MU type connectors, this fiber cleaner can easily remove dirt, dust, oil and grease from an optical fiber adaptor. With the ability to each into the entire area within the connector, it makes cleaning of the ferrule endface a simple task with the push of a button.

For Fiber Connectors (LC/MU):

For Transceiver / Fiber Patch Connection (LC/MU)

This push-type cleaner is specifically designed for the cleaning of ferrule end-faces in MTP/MPO adapters. With the ability to clean all 8/12/24 fibers simultaneously it is a time and cost efficient tool for the maintenance of fiber cables. This cleaner can clean both exposed jumper ends as well as connectors embedded in the adapter.